Over the course of its life, a building frequently undergoes renovation, refurbishment or change of use. In most cases these activities only take place in the parts of the building located above ground level. Nonetheless, the requirements for the power infrastructure in a building can also change significantly over time.

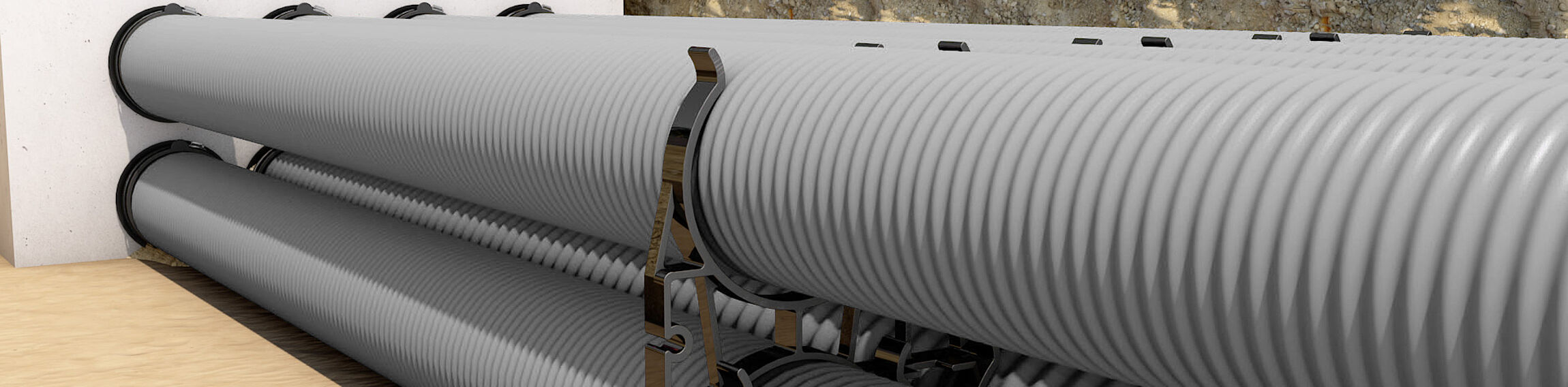

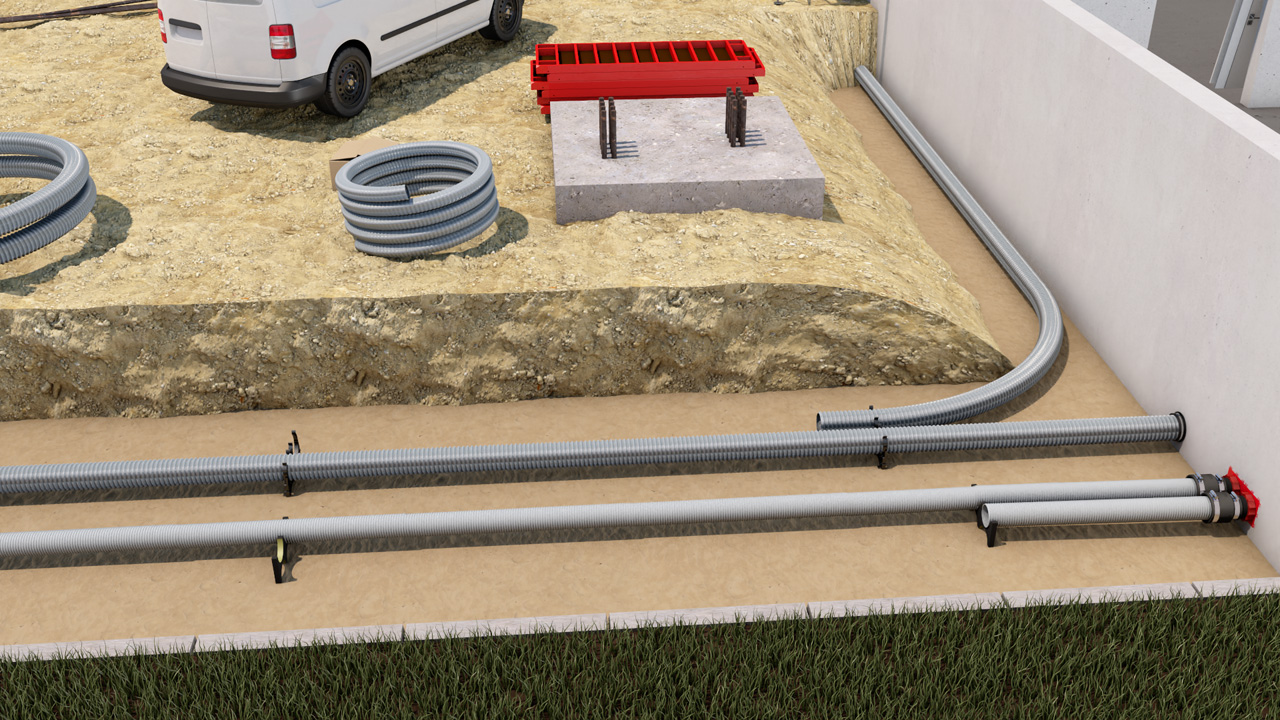

This is where it is recommended to use cable ducts to reduce the required earth moving to a minimum. Cable ducts allow new cables to be installed or old ones to be replaced without having to move a lot of earth. Cable ducts contribute to a sustainable infrastructure for the future.

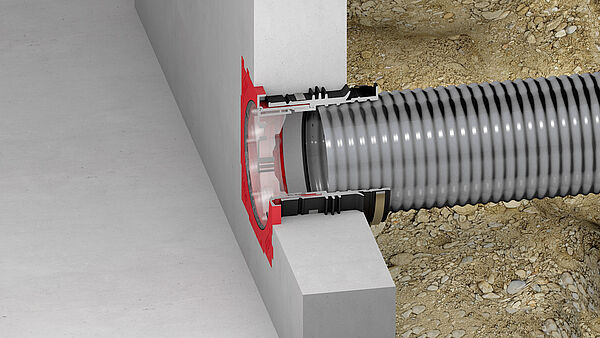

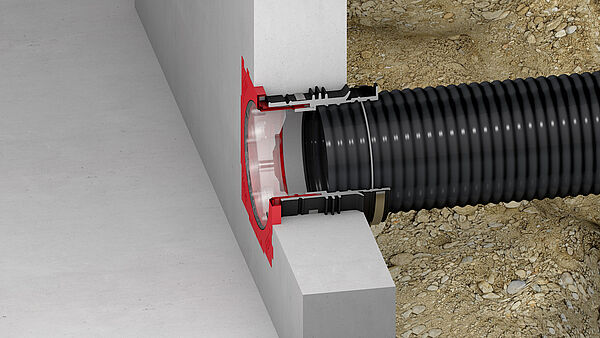

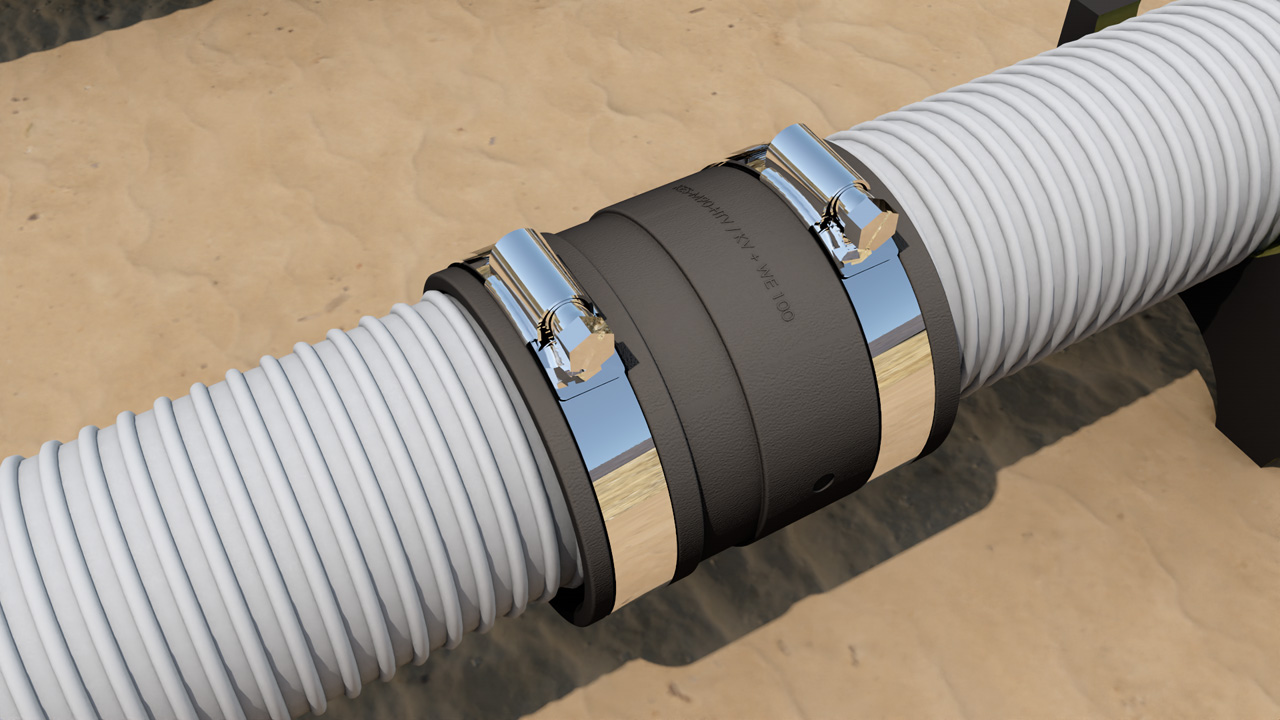

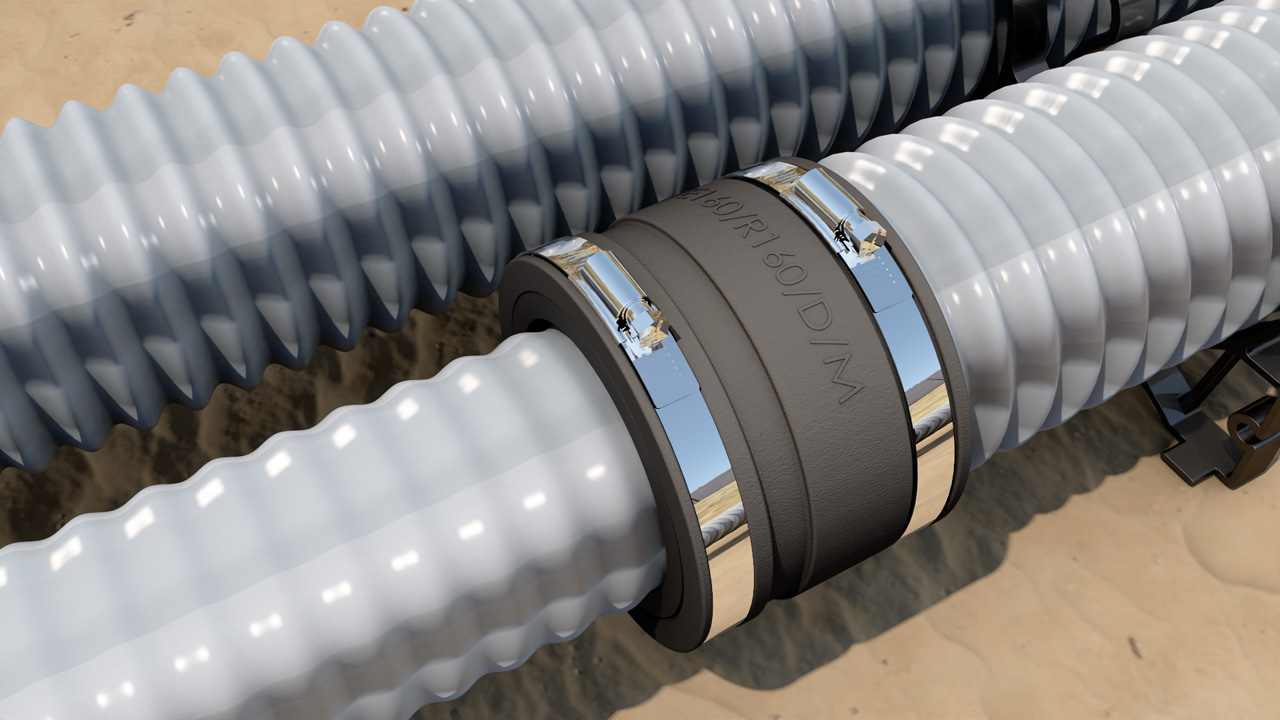

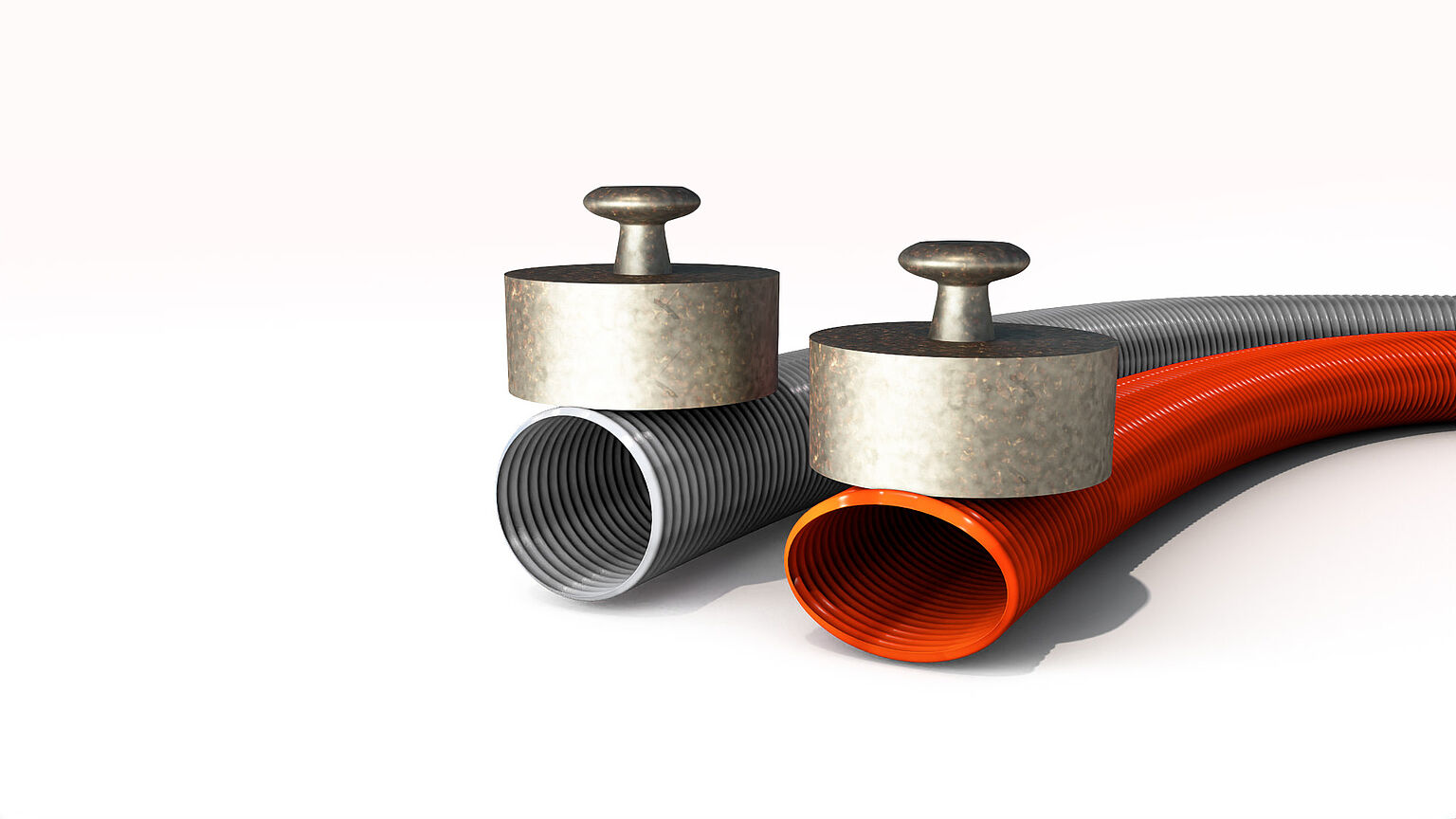

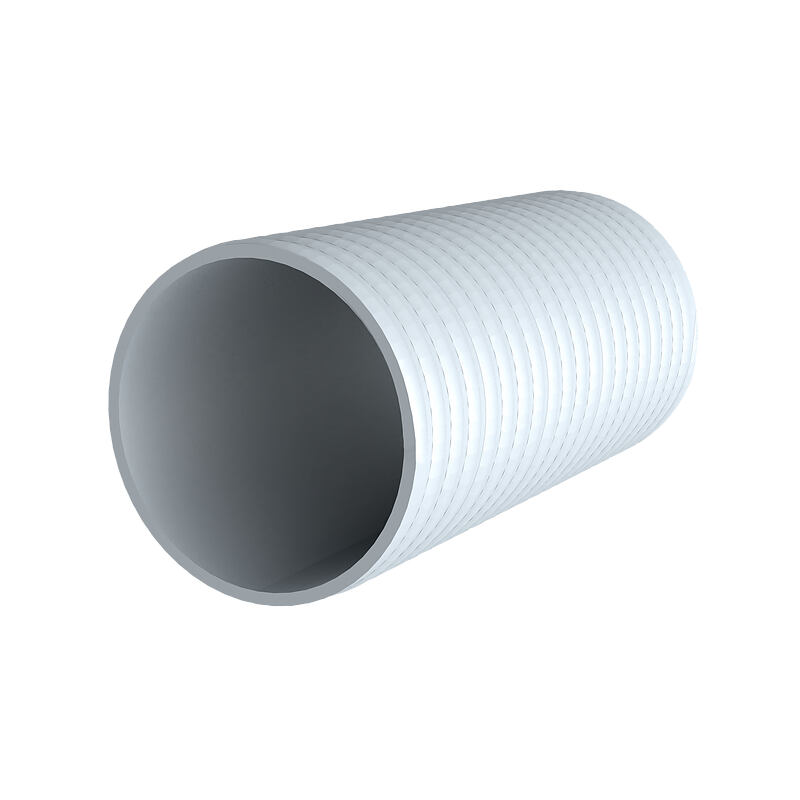

The Hateflex is a polymer cable duct with a smooth inner surface. The combination of hard and soft PVC gives it the properties of flexibility and impact resistance. The cable duct system is available in 5 sizes and provides watertightness up to 2.5 bar.